Contact Us

+91 7900000776

Contact Us

+91 7900000776

Blogs

They both serve a similar purpose—making metal parts more durable—but they go about it in very different ways. And choosing the right one can make a real difference in how long your parts last and how well they perform.

Let’s make it simple.

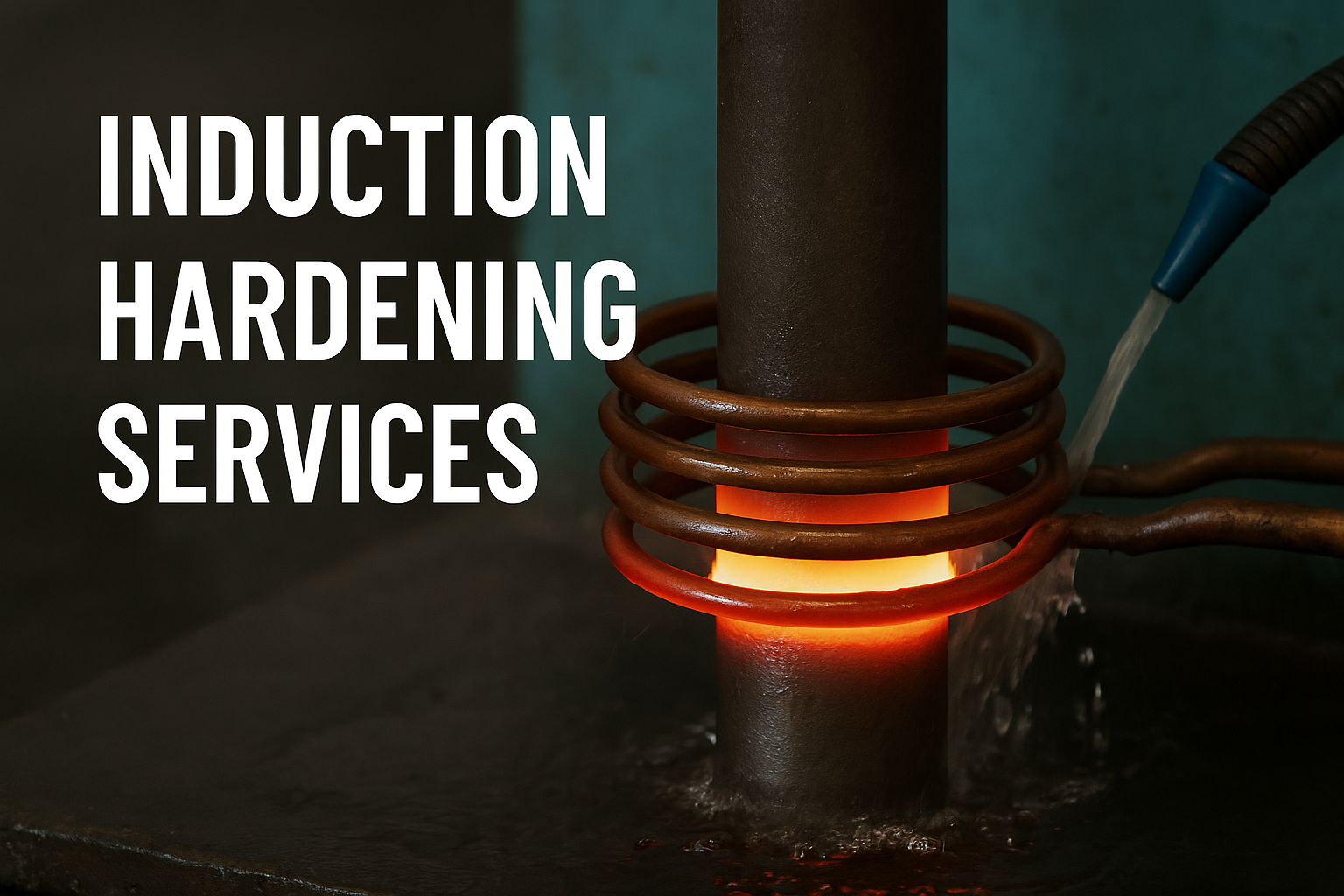

Think of induction hardening like a highly targeted heat treatment. A coil surrounds the metal part (say, a gear or shaft), and electrical currents heat it up from the surface without even touching it. The part is then cooled rapidly to harden that outer layer.

The beauty of this process?

It’s quick, clean, and very precise. You can harden just the areas that need it—no more, no less.

At Thakur Industries, we often recommend induction hardening for parts like:

Gear teeth

Axles and shafts

Industrial rollers

Precision tools

Now, case hardening is a bit more traditional. Instead of using coils and electricity, we heat the entire part in a special environment—usually with extra carbon. Over time, this carbon gets absorbed into the metal’s surface. Once it's cooled, the outer layer becomes harder, while the core stays flexible.

It’s great when you want that deep, tough surface for heavy-duty parts that deal with serious friction and wear.

Here's how they compare at a glance:

Induction hardening is like a sniper—fast, focused, and super accurate.

Case hardening is more like a slow cooker—it takes time but gives you depth.

FeatureInduction HardeningCase HardeningHeat MethodElectric coilFurnace with carbonSpeedFastSlowPrecisionVery highModerateSurface HardnessControlled & shallowDeeper & uniformEnergy EfficiencyMore efficientLess efficientBest ForShafts, gears, pinsHeavy-duty tools, thick parts

If your parts are small or medium-sized, and you need only the outer surface to be tough—like shafts, spindles, or gears—then induction hardening is usually the way to go.

But if your components are bigger, made from low-carbon steel, or need deeper hardening throughout the surface, case hardening might be more suitable.

Still not sure? Don’t worry—we help our clients across Ludhiana and Punjab decide the best method every day.

We’ve spent years helping manufacturers—from automotive parts suppliers in Ludhiana to cycle part makers across Punjab—get more life and performance out of their metal components.

Whether it’s a batch of precision shafts or one-off industrial tools, we bring:

Experience

Advanced machinery

Fair pricing

Honest guidance

You’ll always know what process suits your parts best—no guesswork.

Still wondering whether induction hardening or case hardening is right for your project?

We’d be happy to take a look and suggest the best, most cost-effective solution.

👉 Reach out to Thakur Industries today—Ludhiana’s trusted name in metal hardening and precision heat treatment.